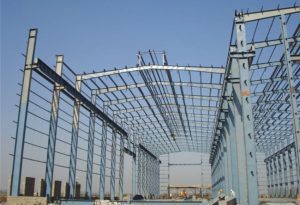

What is ConXTech Erection?

Skilya’s ConXtech is a systemized approach to steel building that includes several standardized structural elements, such as concrete floor systems, rooftop davit systems, stair systems, external wall panel systems, and boltless base plates. Even late in the design process, architects may readily modify the size of the structural grid using ConXCAD, a parametric modeling software package.

ConXTech Structural Frame

The only elements that the structural frame of ConXtech shares are the HSS 88 and HSS 44 columns, 12″ wide-flange beams, two joints, the SMRSF full moment junction, and the ConX Gravity Joint.

There are four inner and four outer collar plates in Skilya’s SMRSF joint assembly. Each inner collar plate has a male dovetail machined into it, and at floor-to-floor intervals, it is welded to each face of the HSS 8×8 column. A female dovetail slot curved to the opposite form of the male projection on the inner collar plate is machined into each outer collar plate. The external sides of the outer collar plate are drilled and mitered to accommodate diagonal bolts. The ends of the 12″ wide-flange beams are robotically welded with outside collar plates.

ConXTech Assembly

A single beam/outer collar plate assembly has to be placed over each male projection on the inner collar plate assemblies on each of the four sides of the HSS 88 column for field assembly. Skilya’s high-strength bolts are put into the diagonal holes in the adjacent outer collar plates and pre-tensioned to create a rigid moment collar assembly that encircles the column once the beam/outer collar plate assemblies have been installed on each face of the column.

Plasma cutting is used to create the ConX gravity connection, which consists of a simple flange cope and hook that slides into a receptacle piece on the HSS 44 column before being fastened with a bolt. The gravity connection is self-aligning, and gravity stabilized, much like the SMRSF complete moment-resisting connection.

Advantages of ConXTech

Skilya’s ConXtech enables considerably higher buildings than could be built in wood in high seismic zones and can provide significant design, time, and cost advantages over traditional steel or concrete.

Skilya’s SMRSF joint has undergone thorough internal testing in addition to 17 full-scale tests at the seismic testing lab of the University of Arizona. It has also undergone peer assessments mandated by San Francisco, San Jose, and Palo Alto, which engineering professionals have reviewed.

Skilya’s Services

The majority of ConXtech’s industrial activities remain secret. The projects listed below demonstrate the scheduling savings and efficiency offered by the ConXtech system. Since its founding in 2016, SKILYA CONTRACTING has shared its expertise and collaborated with others, growing to become one of the top contractors in the eastern province of the Kingdom with a focus on the construction of steel structures, ConXtech erection, and turnkey projects. We guarantee that our customers will receive a high-quality product at a fair price and within an acceptable time frame, thanks to our competence in estimating, construction, project management, and preconstruction services.

This is achieved through working for customers who value direct, honest, and open communication and recruiting top-notch engineers, supervisors, and technicians. ConXtech sells modular steel construction systems that are built on chassis. The business produces traditional buildings, custom structures, and ConX building assemblies. Its steel frames are secured without further welding by lowering and snapping into place.